Finance trends shift fast—explore 5 key processes & tips to stay ahead.

Fill out the form to get your free eBook.

Trends in finance processes change as often as CFOs check their dashboards. This guide takes a look at five key finance processes, offering a step-by-step breakdown of the latest trends and best practices to stay ahead of the curve.

Every day, the value of your company walks out the door with inventory. It’s an ongoing investment that can incur costs like storage, management, and insurance. When inventory is not handled properly, it can hurt your cash flow and lead to disruptions in the supply chain.

Despite inventory being such an important function, 24% of small businesses still track it with a pen and paper. This can affect inventory turnover, lead to dead stock, facilitate spoilage, and create shortages.

Inventory management best practices focus on having the right stock level to avoid downtime, but a minimal amount to cover the necessary costs incurred.

What is Inventory Management?

Inventory management is the process used by businesses to identify, order, store, and sell inventory (raw materials, components, and finished products) from purchase to final sale. The process aims to watch for supply and demand trends so it can guarantee the business has necessary items in stock at all times.

An inventory management system tracks an item from the moment of purchase through its time of use. The best methods include detailed records of all materials to optimize inventory levels and ensure availability across multiple channels.

There are 4 main functions that inventory management serves in a business:

- Segment operations

- Facilitate production requirements

- Anticipate the demand for products

- Safeguard against stock-outs

Different Types of Inventory

The 12 main types of inventory include:

- Raw materials

- Work-in-progress (WIP)

- Finished goods

- Safety stock

- Decoupling inventory

- Packing materials

- Service inventory

- Cycle inventory

- Transit

- Excess and maintenance

- Theoretical

- Repair and Operations (MRO)

Some companies do not recognize MRO as a specific type of inventory.

The Process of Inventory Management

If you’re looking to ditch the spreadsheets and create a solid inventory strategy, there are eight main steps to the inventory management process.

Step 1 – Delivery

This is the point where materials first enter your inventory.

Step 2 – Inspection and Storage

In this step, the product is inspected, sorted, and stored. Many methods can be used during this phase, including dropshipping, cross-docking, or whatever works best for the storage space.

Step 3 – Monitoring

Inventory levels are monitored consistently. This can be done through inventory cycle count, physical inventory, or perpetual inventory software.

Step 4 – Ordering

At this point, customers will purchase your inventory in a physical location or through an online marketplace. Depending on the customer and credit line, this step may require a purchase order that lists details like the amount of inventory and cost of goods.

Step 5 – Approval

This is typically a task you can automate through the point of sale (POS) system. If your business uses dropshipping, this would be where the order gets passed on to the supplier.

Step 6 – Items Taken from Stock

At this point, goods are located and removed from inventory. Items are found using a SKU number or barcode, then packaged, shipped, or delivered directly to the customer.

Step 7 – Inventory is Updated

If you run a perpetual inventory program, stock levels will change automatically, in real-time. This is immediately reflected in the number of units listed in an inventory management software platform.

In a manual inventory system, changes are discovered when you take physical inventory on a spreadsheet or other checklist. This can slow down the supply chain and lead to disruptions in workflow.

Step 8 – Automated Reordering

In the last step of managing inventory, low stock levels and inventory counts should trigger reordering and replenishment. To optimize this phase, a business can calculate the reorder point for each product. This allows you to get the goods you need to meet demand faster and more efficiently.

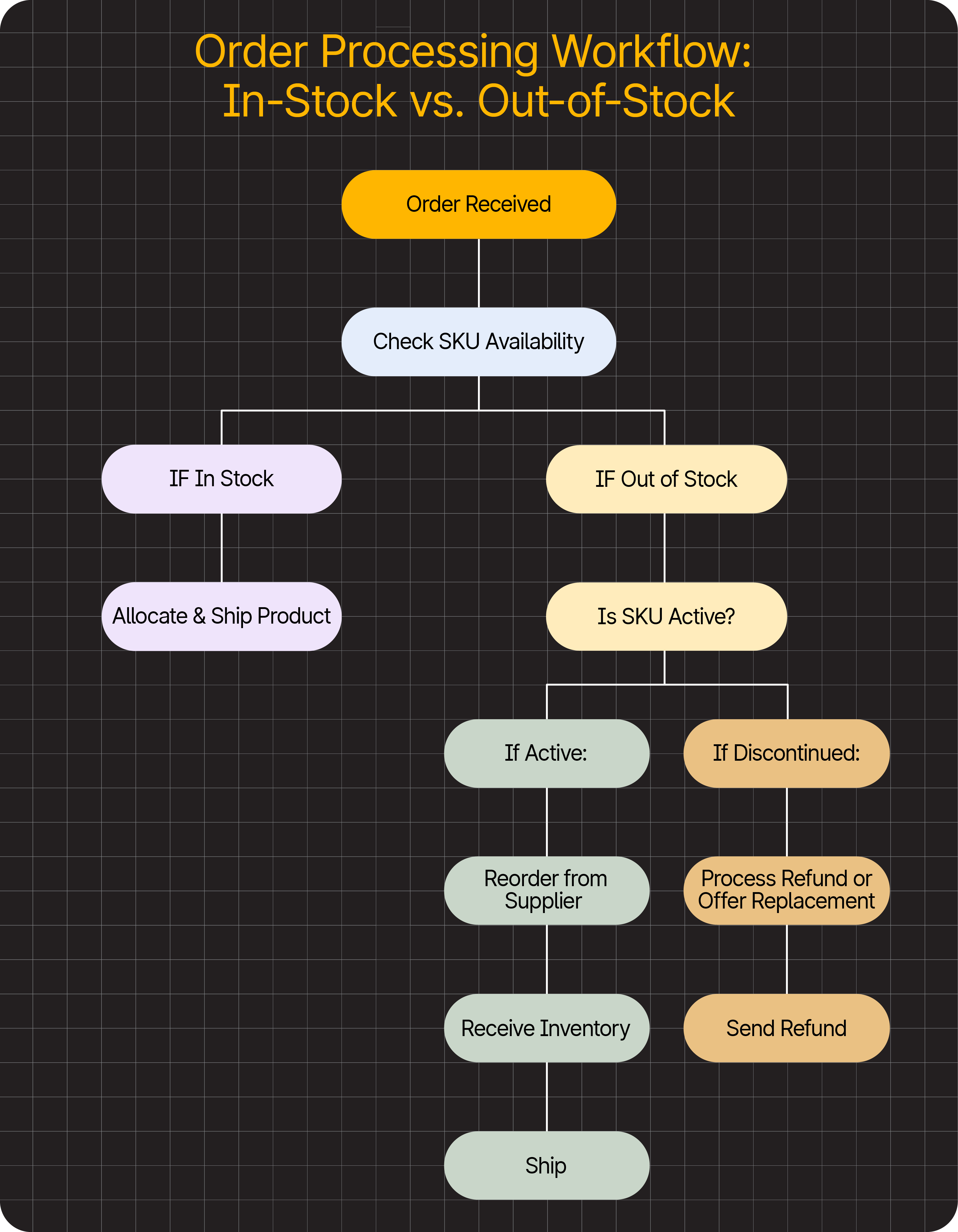

Inventory Management Process Workflow

Steps in the inventory management process can be performed more efficiently by tracking and reviewing each task. This helps to eliminate waste, discover issues, and reallocate resources to a step that needs it, in order to increase profit.

You might be motivated to create an inventory process map that lays out every step of the program. Many variables are specific to your business and this can help to better visualize the end-to-end system. Mapping everything out better prepares for any sudden changes in supply and demand.

For example, if an order comes in and you can’t fulfill the amount of product, a process map demonstrates what to do. This can include the next step, like placing a backorder or sending an immediate refund. Your map can also show what to do based on an item’s value.

Methods of Inventory Management

Inventory management is not a “one-size-fits-all” solution and what works for one organization, can be a complete disaster for another. As order management and inventory controls evolve, new methods are added to a long list of strategies.

Here are some of the more common methods of inventory management you will come across:

Just-in-Time Inventory (JIT) Management

This is the most common method of inventory management, and it works well with enterprise resource planning (ERP) systems. In the JIT management style, companies try to minimize or eliminate inventory levels by receiving items only when they are really needed. The just-in-time strategy eliminates storage costs, facilitates warehouse management, and creates less overall waste.

However, JIT can backfire on you if there is a sudden spike in demand or supply chain management is unpredictable. In this case, a business can end up with empty shelves or overstock in the wrong places.

Materials Requirement Planning (MRP)

The other common method of inventory management is called materials requirement planning (MRP). This involves anticipating the items, materials, and supplies a facility might need in a given time, and purchasing them accordingly.

An efficient MRP system requires concise recordkeeping and reliable tracking of materials so they can be located as quickly as possible. The longer it takes, the less likely an MRP plan will work successfully.

Batch Tracking

In the batch tracking method, a business groups similar items together. For example, materials with the same expiration date or that came in on the same shipment are “batched” together. This can create support for additional methods like “First in, First Out” (FIFO).

ABC Analysis

This is a strategy that divides stock based on levels of control. Inventory is separated into three separate categories, A, B, and C, with A requiring the most recordkeeping, and C requiring the least.

Cycle Counting

Rather than quantifying all inventory items at once, some storerooms (think retail business) use cycle counting. This means only a handful of items are counted each day. Over the course of a quarter or year, the entire inventory would be calculated with a minimal investment of time.

Demand Forecasting

In this method, predictive analytics is used to determine future demand. For example, demand forecasting for MRO stock can help to predict how many of a given part will be used in the upcoming months. This makes it possible for a business to recommend purchases before a part is even needed.

First In, First Out (FIFO)

In this method, stock items are used in the order they are received. This works best for companies that sell items with a shelf life. It also works for fast-moving inventory as well.

Last In, Last Out (LIFO)

In this strategy, just as it sounds, items that are received last, are the first to go out. This can help to minimize costs of inventory, which becomes more expensive, the longer you hold onto it.

Minimum Order Quantity

In this strategy, a business never orders more of any given item than what is needed. The minimum order quantity is a count of the lowest number of an item you need to order from a supplier. This helps to minimize carrying costs and keeps the workflow moving faster.

Stock Control

In this inventory control process, items are managed from the moment they are ordered. This means tracking throughout storage, movement, and usage, to a final destination or disposal.

Kanban Method

The Kanban method is a scheduling system that helps to keep inventory levels low. The system is built around “bins” that are used to separate materials used in production. This is a major component of the JIT and/or lean manufacturing strategy.

For example, if you run a meatpacking plant, Kanban ensures you have enough meat and packing materials on hand to meet fulfillment needs. So, if a new order comes in that requires 300 pounds of beef, you use what’s on hand first. Once this “bin” of materials is used up, you place an order with the supplier to finish fulfillment. This process is repeated every time an order is received.

Inventory Control and Formulas

Over time, multichannel processes have been created to help organizations deal with the complexity of inventory control. To streamline inventory management and optimize stock levels, understanding these formulas is crucial. Here are a few to get you started:

Quality Control

An essential part of inventory control, quality control is about working with suppliers who have the same standards as you do. This helps to develop a strong relationship over time and ensures your stock consistently meets high-quality goals.

Organizational Control

Stock should be meticulously organized, which begins by labeling all items with a SKU number that is easy to read. It starts with an initial stocktake and then the right inventory management techniques to monitor movement and levels.

Reorder Point Formula

This formula helps a business determine the right time to order more stock. To calculate this figure, you need your lead time demand (in days) and safety stock (also in days).

Using this equation, a company can determine the minimum amount of stock they should have before reordering, then manage inventory accordingly.

Economic Order Quantity (EOQ)

The economic order quantity (EOQ) shows the optimum inventory you should purchase to minimize the cost of ordering and holding stock. To calculate this formula, you’ll need to know:

- Annual fixed costs

- Demand in units

- Carrying costs per unit

Days of Sales Inventory (DSI)

DSI is a formula that determines the average number of days it takes for a business to sell off inventory. It’s a metric analysts use to determine the efficiency of sales. The higher the DSI, the less likely an organization is managing inventory effectively. Adversely, fewer stock items on hand is an indicator of strong sales and less overhead.

Benefits of Inventory Management

The major benefit of an effective inventory management system is that a business can always fulfill open orders and raise profits. An accurate program improves a company’s efficiency and productivity, while reducing costs associated with excess inventory. Advantages of an accurate program include:

Save Money

A deeper understanding of stock trends means a more intelligent approach and calculated use of inventory. A business is better able to use the stock on hand, without needing more space. All of this decreases the costs tied up in management and decreases the amount of inventory that goes unsold or is wasted.

Improved Efficiency

Every item in inventory costs more the longer you hold onto it. By keeping inventory as lean as possible, a business reduces overhead. This is because purchases that may not be immediately necessary are eliminated and item obsolescence is minimized. You can quickly identify needed items, acquire those in a timely manner, and move them through the system with minimal disruptions.

Better Cash Flow

Whether your business keeps a production line up and running or moves finished units through retailers, organized inventory management helps to improve and forecast cash flow. A business is better able to fulfill orders, assess usage, and minimize costs. With proper inventory management, a company spends more money on inventory that sells, so cash is always moving swiftly through the business.

Accurate Forecasting

When a business is on top of inventory management, it can better anticipate what items are needed to keep things running smoothly. This creates a solid inventory forecasting process, which helps other areas like financial reporting, minimized stockouts, and JIT ordering.

Streamline Organization

When inventory is managed well, you’ll always know exactly where everything is located, how much you have, and what it’s used for. For example, an MRO inventory that is tracked would be limited to only those items linked to your assets, along with general supplies and free stock. This means less waste in terms of time and purchasing decisions.

Improved Business Relationships

This means for all parties involved. Effective inventory management works to incentivize more communication and consistent collaboration with suppliers. Reoccuring orders may happen more frequently, with the ability to negotiate better prices. When done right, inventory management helps the cream rise to the top. You’ll find yourself dealing with higher-quality suppliers who meet your needs more reliably.

Additionally, improved inventory controls helps to develop more loyal customers. That’s because they are receiving orders faster and more efficiently, without having to wait.

Importance of Inventory Management

Successful inventory management rides a fine line between too much stock and not enough. There is never a perfect number since demand will fluctuate, but an effective strategy limits the risk of stockouts and inaccurate recordkeeping.

Inventory management is crucial to a streamlined supply chain because a business must balance customer demand with cash limitations and storage space. This provides improved visibility into the supply chain (like procurement, production, and fulfillment) so supervisors can better coordinate lead times and reduce stock levels.

There are several reasons to adopt an effective inventory management system right now, including:

More Strategic Planning

Inventory management is important because it brings sense to the data around you and allows for more informed decision-making. The entire goal is to minimize holding costs while optimizing inventory. It can help you distinguish products between well-performing and shelf-eaters. This helps to free up cash flow and improve working capital management.

Used in conjunction with automation, inventory management can also help to analyze and forecast a customer’s purchasing pattern. Then, a business can restock inventory based on actual data. Not only does this generate more revenue, but you can stockpile inventory based on daily sales patterns.

Improves Timing

In this day and age, customers demand the most of quality and time. Late delivery due to inventory issues can cause issues with sales and brand distrust.

Inventory that is properly organized and managed makes it easier to locate items when an order arrives and hence, deliver them quickly. This leads to a higher rate of customer satisfaction and retention.

Keeps Costs Low

Consistent stock management helps a business better understand the value of inventory items. This makes it easier to only order what is needed, not a cent more or less. Accurate forecasting means you can order the right amount, the majority of the time, which saves on costs involved in overstocking, processing, backorders, storage, and more.

Increases Productivity

If you’re spending an inordinate amount of time searching for products, a robust inventory management strategy will help. This involves allocating specific items to specific locations, making it easier to track and ship. Not only does this save time and effort, it helps to divert labor resources towards more pressing matters. It also decreases the likelihood of human error and leads to a higher rate of productivity.

Greater Compliance

In some cases, public companies must track inventory as a requirement for compliance with the SEC (Securities and Exchange Commission). The Sarbanes-Oxley (SOX) Act states that companies must document their inventory management process to prove compliance.

Improving Inventory Management

If you already have a system in place for managing inventory, it can always be improved. Keeping regular and accurate records, while taking the occasional physical stock count, are two ways to get started. You should also be aware of inventory conditions at all times. This is especially the case for perishable items.

Other ways to improve inventory management include:

- Slow-moving inventory goes out first

- Work to better understand your supply chain

- Set minimum stock levels

- Minimize shrinkage at all times

- Get flexible with SKUs

The right inventory management strategy can provide your organization with unmatched visibility in real-time, which can help stakeholders make critical business decisions. It’s one of the most overlooked ways to gain a competitive advantage and decrease costs. The more organized your stock is, the more prepared your business will be for growth and future success.

Order received

- Search SKU

- Item is in stock

- Ship product

- Item is in stock

- Search SKU

- Item is out-of-stock

- Re-up with supplier

- Receive items and ship out

- No longer carry

- Re-up with supplier

- Item is out-of-stock